Specialized Industry Solutions, LLC

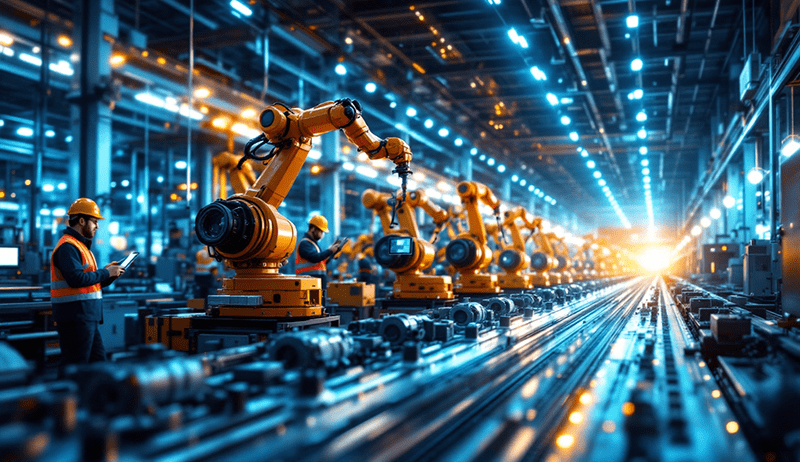

SIS—Specialized Industry Solutions—offers a single-source capability, which ensures control over every aspect of system development and cost.

Products and components can be assembled using a variety of methods, including servo, hydraulic, and pneumatic.

It can move and store totes or products in required locations. The systems are custom-designed, built, and programmed to meet any need.

Leak and pressure testing are types of testing that can be performed. Vision systems, load cells and color sensors can be used to inspect components.

Why Choose Assembly Solutions for Your Next Project?

Expertise and Experience: With over thirty years of combined experience, ASI's team, led by Marty Grimes, Michael Grimes, and Rob Grimes, brings a wealth of knowledge in industrial technology applications. This expertise ensures that your project benefits from innovative solutions tailored to your specific needs.

Comprehensive Solutions: ASI represents a range of industrial technology companies, offering solutions in leak testing, plastic welding, plastic joining, screw & nut blow feed systems, clip placement feed systems, radial riveting, material handling, and part marking. This breadth of offerings means you can find multiple solutions under one roof, simplifying your sourcing process..

Industry Recognition: ASI's dedication to professional sales representation and continuing education is recognized through their membership in esteemed organizations like the Manufacturers and Agents National Association (MANA) and Manufacturers’ Agents of Cincinnati (MAC). This commitment to excellence ensures that you work with a company that values industry standards and best practices.

Geographical Coverage: Serving Kentucky, Southern Indiana, Southern Ohio, and Tennessee, ASI has a strong regional presence, making them an accessible and reliable partner for local businesses.

Time and Efficiency: Partnering with ASI can save you valuable time. Their automation solutions help fill in the gaps left by manual labor, increasing production throughput and allowing your team to focus on strategic planning rather than reactive problem-solving.

Support and Innovation: Clients value ASI for its timely support and the fresh ideas it brings, moving away from the 'this is how we have always done it' mindset. This approach ensures that your project benefits from the latest in manufacturing technology.

.png?width=600&height=162&name=assembly-solutions-logo-retina%20(1).png)