Visumatic

Automated Screwdriving & Fastening

Visumatic serves a wide range of industries with field-proven equipment and systems. Our expertise provides manufacturers with turnkey functionality and dependable solutions.

Companies everywhere trust our team to deliver fastening technologies that enhance product quality, increase efficiency, and optimize their assembly processes.

You can depend on Visumatic for the most trusted automatic screwdrivers on the market. Our handheld automatic screwdriver line begins with entry level systems, like the basic locking bit system, the most reliable handheld screw feeding and driving system available. Our advanced and specialty handheld automatic screwdrivers work where conventional tooling can’t, providing operator assistance where screw placement is difficult.

Trust Visumatic for the most reliable fixtured screwdriving systems on the market. We have your fixtured screwdriving system component needs covered, from power modules to custom feeder systems. Whether you need a multi-spindle fixtured system, or a single feed and drive system, Visumatic has high performance products to meet your needs. Visumatic’s automatic fixtured screwdriving systems deliver repeatable fastening and enhanced productivity.

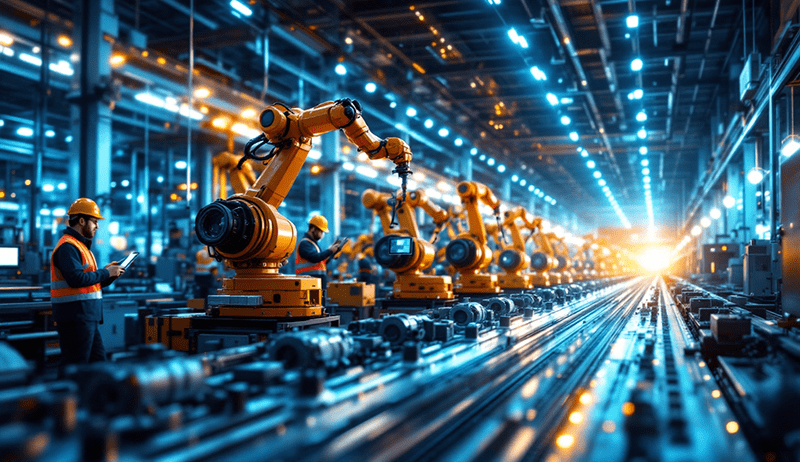

You can count on Visumatic for innovative robotic screwdriving systems on the market. Visumatic is your source for robotic componentry and cobot screwdrivers for collaborative systems and multi-access workstations. Visumatic’s robotic screwdriving driving systems enhance productivity with dependable performance that virtually eliminates downtime. Our automated screwdriving systems are backed by a 100% unconditional guarantee and supported by a dedicated on-call customer service group. Put the advantages of Visumatic robotic screwdriving systems to work to streamline your assembly processes

Automated Fastening Systems

Visumatic is your source for dependable automatic fastening systems that offer maximum assembly efficiency and accuracy for optimal performance.

Engineered for everything from nuts to pins, you can count on Visumatic’s automatic fastening systems that perform reliably to virtually eliminate downtime and maximize productivity.

Our broad experience in specialty automatic fastening means you can rely on us to handle every fastening challenge your company faces.

Customized technical manuals back each guaranteed system, and your team is supported by our dedicated on-call customer service group. Put the advantages of Visumatic automatic fastening systems to work to streamline your assembly processes.

Feed direct to insert point technology for rapid pin insertion.

Flexible mounting options allow for direct tooling plate installation with a customized adapter plate that matches your actuation method. Tooling tips are custom engineered to interface with component surface details allowing maximum assembly efficiency and accuracy.

Nut feed direct to tooling tip technology for rapid automatic driving.

Engineered designs to automatically feed and drive a variety of nuts including flange, hex, nylock, captivated star washers, and other specialty nuts. Engineered part interface tooling conforms to production parts providing a repeatable, accurate nut rundown cycle.

Ergonomic improvements eliminate time consuming ring separation and orientation.

Visumatic leads fastening innovation again with the automatic ring application system, unavailable anywhere else on the market. Presentation tooling is engineered to fit your ring and set brazing ring position on the tubing.

Auto-feed direct to insert point technology for rapid clip insertion.

Flexible mounting options allow for direct tooling plate installation with a customized adapter plate that matches your actuation method. Part interface tooling is engineered to mate with your part tower design for repeatably accurate and efficient assembly.

Custom engineering ~ the possibilities are endless.

Flexible mounting options allow for direct robot EOAT installation with a customized adapter plate that matches your actuation method. Tooling tips are custom engineered to interface with component surface details allowing maximum assembly efficiency and accuracy.

Why Choose Assembly Solutions for Your Next Project?

Expertise and Experience: With over thirty years of combined experience, ASI's team, led by Marty Grimes, Michael Grimes, and Rob Grimes, brings a wealth of knowledge in industrial technology applications. This expertise ensures that your project benefits from innovative solutions tailored to your specific needs.

Comprehensive Solutions: ASI represents a range of industrial technology companies, offering solutions in leak testing, plastic welding, plastic joining, screw & nut blow feed systems, clip placement feed systems, radial riveting, material handling, and part marking. This breadth of offerings means you can find multiple solutions under one roof, simplifying your sourcing process..

Industry Recognition: ASI's dedication to professional sales representation and continuing education is recognized through their membership in esteemed organizations like the Manufacturers and Agents National Association (MANA) and Manufacturers’ Agents of Cincinnati (MAC). This commitment to excellence ensures that you work with a company that values industry standards and best practices.

Geographical Coverage: Serving Kentucky, Southern Indiana, Southern Ohio, and Tennessee, ASI has a strong regional presence, making them an accessible and reliable partner for local businesses.

Time and Efficiency: Partnering with ASI can save you valuable time. Their automation solutions help fill in the gaps left by manual labor, increasing production throughput and allowing your team to focus on strategic planning rather than reactive problem-solving.

Support and Innovation: Clients value ASI for its timely support and the fresh ideas it brings, moving away from the 'this is how we have always done it' mindset. This approach ensures that your project benefits from the latest in manufacturing technology.

.png?width=600&height=162&name=assembly-solutions-logo-retina%20(1).png)